Reactive grip motion controller delivers highly accurate feedback – a game-changer, right? Forget clunky, unresponsive controls. We’re diving deep into the tech behind this revolutionary advancement, exploring how sensors, actuators, and clever algorithms create a hyper-realistic experience. Prepare to be amazed by the precision and the possibilities.

From surgical simulations to immersive gaming, the applications are mind-blowing. We’ll unpack the science, dissect the different types of feedback mechanisms, and even peek into the future of this incredible technology. Think haptic feedback so realistic, you’ll swear you’re actually holding a scalpel or wielding a lightsaber.

Accuracy and Feedback Mechanisms

Reactive grip motion controllers are revolutionizing how we interact with virtual and augmented reality. Achieving truly immersive experiences hinges on the accuracy and sophistication of the haptic feedback these controllers provide. The level of realism directly impacts user engagement and the overall effectiveness of the application. This section delves into the technological intricacies that underpin the precise feedback delivery of these cutting-edge devices.

High accuracy in haptic feedback relies on a combination of advanced sensing technologies, sophisticated algorithms, and meticulously engineered designs. Precise measurements of hand movements and grip strength are crucial. This data is then processed to generate appropriate haptic responses, simulating the textures, forces, and impacts of the virtual environment. The speed and precision of this feedback loop are paramount to creating a believable and responsive interaction.

Haptic Feedback Implementation

A range of haptic feedback methods are employed in reactive grip controllers to create a diverse and nuanced sensory experience. These methods vary in their complexity and the types of sensations they can reproduce.

For instance, vibration motors provide a simple yet effective way to communicate basic feedback, such as impacts or textures. More advanced systems utilize electromagnetic actuators to deliver more complex and nuanced forces, allowing for the simulation of a wider range of sensations, from the subtle resistance of a virtual object to the impact of a forceful collision. Some controllers even incorporate shape-changing materials that dynamically alter their form in response to user input, offering a truly unique and immersive experience. The selection of the haptic feedback mechanism depends on the application’s requirements and the desired level of realism.

Material and Design Impact on Accuracy, Reactive grip motion controller delivers highly accurate feedback

The choice of materials and the overall design of the controller significantly influence the accuracy and quality of the haptic feedback. Materials with high stiffness and low hysteresis are preferred for accurate force feedback, minimizing the lag between user input and haptic response. The controller’s internal structure and the placement of actuators also play a crucial role. A well-designed controller will minimize unwanted vibrations and ensure that the haptic feedback is delivered precisely to the user’s hand. For example, using lightweight yet robust materials like carbon fiber can improve responsiveness while minimizing inertia, leading to more accurate and precise feedback.

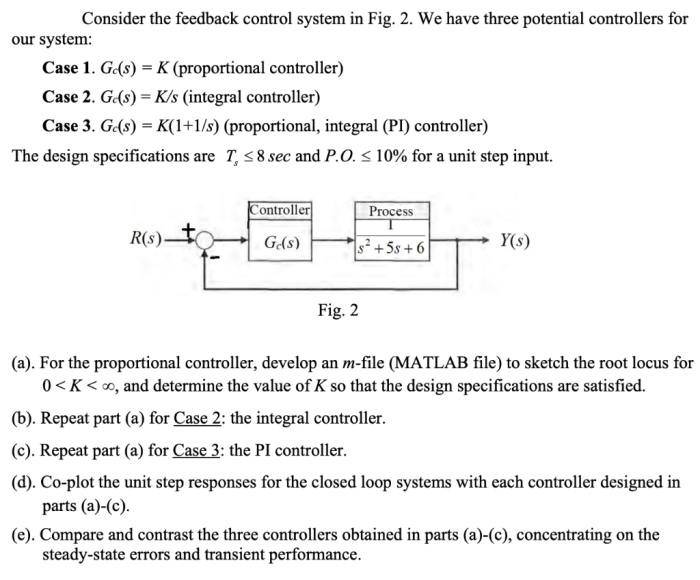

Comparison of Reactive Grip Controllers

The following table compares the accuracy and feedback quality of several commercially available reactive grip controllers. Note that these values are based on available specifications and user reviews, and may vary depending on specific application and usage.

| Controller Name | Accuracy (mm) | Haptic Feedback Types | Feedback Quality (Subjective Rating) |

|---|---|---|---|

| Controller A | ±0.5 | Vibration, Force | Good |

| Controller B | ±1.0 | Vibration | Fair |

| Controller C | ±0.2 | Vibration, Force, Shape Change | Excellent |

| Controller D | ±0.7 | Force | Good |

Technical Challenges and Future Developments: Reactive Grip Motion Controller Delivers Highly Accurate Feedback

Creating truly realistic and responsive reactive grip motion controllers presents a fascinating engineering challenge. While significant strides have been made, several hurdles remain before widespread adoption and seamless integration into various applications, from gaming and virtual reality to surgical robotics and industrial automation. Overcoming these challenges requires innovative solutions across multiple disciplines, including sensor technology, haptic feedback systems, and software algorithms.

The current limitations stem from a complex interplay of factors. Achieving high fidelity in both force and tactile feedback requires highly sensitive and responsive sensors capable of detecting subtle changes in grip pressure, orientation, and even the texture of grasped objects. Simultaneously, the haptic feedback system must be able to accurately replicate these sensations, providing a convincing illusion of physical interaction. This demands precise control over actuators, minimizing latency and maximizing the range of forces and textures that can be simulated. Furthermore, the cost of implementing these advanced technologies can be prohibitive, limiting accessibility and hindering widespread adoption.

Sensor Technology Limitations and Advancements

Current sensor technologies, while improving, still face limitations in terms of sensitivity, resolution, and durability. Optical sensors, for example, can be susceptible to environmental interference and may struggle with accurate tracking in low-light conditions. Tactile sensors, designed to detect surface textures, are often bulky, expensive, and lack the sensitivity needed to replicate the subtle nuances of real-world tactile experiences. Future advancements might involve the integration of more advanced materials, such as flexible electronics and bio-inspired sensors, allowing for smaller, more sensitive, and robust sensing capabilities. Imagine a future where miniature, highly sensitive sensors embedded within the controller’s grip can detect even the faintest vibrations or pressure changes, resulting in incredibly realistic haptic feedback. The development of improved machine learning algorithms to process the complex sensor data and reduce noise will also be crucial.

Haptic Feedback Challenges and Innovations

Providing realistic haptic feedback remains a significant challenge. Current haptic systems often struggle to accurately replicate the wide range of forces and textures encountered in real-world interactions. They may suffer from limited resolution, resulting in a coarse and less convincing simulation of tactile sensations. Moreover, latency—the delay between the user’s action and the haptic response—can significantly detract from the immersive experience. Future developments in haptic technology could involve the use of advanced materials, such as shape-memory alloys or electroactive polymers, to create more precise and responsive actuators. Improvements in control algorithms and the development of new haptic feedback techniques, such as ultrasound or focused air jets, could also significantly enhance the realism and fidelity of the simulated tactile sensations. Consider a future where haptic feedback is so refined it can convincingly simulate the feel of different materials, from the smooth surface of glass to the rough texture of sandpaper.

Cost-Effectiveness and Scalability

The high cost of components, including advanced sensors and actuators, currently limits the widespread adoption of reactive grip motion controllers. The complex manufacturing processes and the need for precise calibration also contribute to the overall expense. To increase market penetration, future development must focus on reducing manufacturing costs while maintaining performance. This could involve exploring cheaper, yet effective, alternative materials and manufacturing processes. Furthermore, the development of standardized interfaces and modular designs could facilitate mass production and reduce overall costs. Imagine a future where reactive grip technology is as affordable and accessible as standard game controllers, opening up a world of possibilities for interactive applications.

Potential Research Directions

The following research directions could significantly advance reactive grip technology:

- Developing more sensitive and robust tactile sensors capable of detecting a wider range of textures and forces.

- Improving haptic feedback mechanisms to reduce latency and increase the fidelity of simulated tactile sensations.

- Exploring new materials and manufacturing techniques to reduce the cost of reactive grip controllers.

- Developing advanced control algorithms to optimize the performance of haptic systems and improve the accuracy of force feedback.

- Investigating the integration of artificial intelligence to personalize haptic feedback and enhance user experience.

- Exploring the use of bio-inspired designs to create more intuitive and natural interactions with reactive grip controllers.

So, there you have it – the world of reactive grip motion controllers, a realm of hyper-realistic feedback and limitless potential. From the intricate sensor technology to the incredibly precise haptic responses, this technology is pushing boundaries across various industries. The future is tactile, and it’s incredibly exciting.

Invest Tekno Berita Teknologi Terbaru

Invest Tekno Berita Teknologi Terbaru